Based on What i start process and write down the point in A4 paper.

What

does mean analog?

Analog is the

opposite of digital defined doing on manual by handmade. Any technology, such

as design clothes, that doesn't have digital to print out, for example do it in

using the analog silk screen in the printed image to paper. Another definition of analog is something

that is similar to that of another, the two are

said to be analogous. Analog copies substantiate in different ways from and are

often inferior to the original. Besides that, the easily identified original is

privilege above a copy. the Original identity may be consist of elements that

cannot be perfectly reproduced, for example, the original brush painting, the

three dimensional quality of the paint on the canvas, the smell of paint, and

the texture experience of paint in the canvas. Analog copies have an identity

that derives from but need to separate from the original. Even digital can

copying technology can produce only for reproduction, not a replication, of

such an analog creation.

What

does mean digital?

Digital is the

development programming of the future because it gives us an accurate way to

represented data and a simple way to mechanically store and manipulate of data.

For this digital world is inevitable, so we hope this explanation will help

everyone to understand to the digital concept. For example like direct printing

by plate imaging system or printing the process in computerized control ink jet

printers.

What

the definition of Analog printing?

Analog printing mean refers

to the printing process in which manually prepared screen or plates are used

for printing any type of material. Textiles printings are analog printing uses

master in the form of screens, block printing, roller printing, and so on.

All stages involved in analog printing are given as follows

1.

To print any material first step is

to create files for each and every color used in printing and a then to

separate those files with respect to their colors.

2.

The second step is to create screen

for every file with respect to their colors. It means every color needs a

separate screen. These screens are produced by heating process.

3.

Third step is to dry the screens

4.

Fourth step is about printing. But

here again one has to print each colored file separate from rest and after one

and other, all colors will be printed.

5.

Dry the colors

6.

Finally keep the screens safe for

next time usage.

FOR EXAMPLE:

Analog Typography/

type printing.

Letterpress printing

Analog Stamping type

and pattern.

Analog art

printing.

Analog photography

Analog motion

graphic

What

does mean analog screen printing (Silk screen printing)?

Silk screen

printing is kind of ancient art can be traced back to thousands of years to

origins of Japanese fabric dying. In the 1960, Andy Warhol begin to use it to

generate iconic images, such as Campbell soup cans and his portrait of Elvis

Presley and Marilyn Monoroe, and in doing so brought the practice of art the world's

attention. Over the year, already developed into a very popular used in the

production of high-quality art print, the artist is able to retain control over

the entire printing process, the end result.

Screen printing

also as know as called serigraphy is a method of creating as image on paper,

wood, glass and metal, fabric to print an image like some t-shirt, logo and so

on. The techniques are used both for making fine art prints and commercial

applications such as printing a company’s logo on the t-shirts.

For example:

Here are the

steps to printing onto paper for one or multi-color designs:

1. Attache a pair of hinge clamps to your work surface. Make

certain they are square and straight when you screw them in.

2. Place your printing screen in the hinge

clamps.

3. Tape two pieces of cardboard box to the underside corners of your printing screen nearest you.

3. Tape two pieces of cardboard box to the underside corners of your printing screen nearest you.

4. Lightly spray your print surface with photo

adhesive or spread a tiny amount of table adhesive over the area so that it is

slightly tacky.

5. Take a large piece of transparent paper and place it over

your work surface; taping it on one side only to your print table.

6. Print one pass of your image onto the

transparent paper.

7. Place your paper under the transparency so that your image

will print where you want it to.

8. Flip the transparency away from your print area.

9. Mark the bottom and side of the paper edge with masking tape.

These will be your registration marks- don’t remove them.

10. Pour a bead of ink along the bottom of your screen area

(the well).

11. Flood the screen with the screen in a

raised position then print with the screen down.

12. Print all

pieces of paper with this screen and let them dry.

13. Flip your transparency paper back onto your print

surface. And print the second color screen. Use that new print as a guide and

place one of the printed pieces of paper so the colors line up with the acetate

print. Then place new registration tabs for this piece of paper.

14. Repeat these steps for each color you have in your

design.

What

the definition of Analog Digital?

Analog digital is

refers to printing process in which computerized control ink jet to the

printers and laser printers are used for the printing of any type on material.

If using computer is linked to printing machine (Ink jet printer) Conversion of electronic design data in the form of analog image with the help

of a lots or pixels and no need of design screens, block or design rollers.

Also known as printing without screens or plate less printing.

A digital screen

printing has brought new change in the printing world and also has a benefit of

this printing work. The printing can be high in rates and you will find that

the quality of the print is far much better than ordinary printers. For example

many t-shirt companies are giving the order to digital printing companies to

making a digital print on the shirt so they can introduce their shirt in the

market as a new fashion and also can attract more customers towards their

garment product.

Digital screen

product is the one fastest and innovative ways of creating a printed material.

it can helpful in printing logo, image, t-shirt designs, cloth designs and so

on. It is convenience and efficiency. The digital screen printing is very

important to process. Most of the business establishments, especially in the field

of advertising, name card, magazine, packaging need to have digital printing

tools with them. That is the one must know how the different of digital

printing processes as well as concepts. The digital screen printing uses

specific type of ink and using the toner to produce great quality images. The

price of the toner is highly competitive in the market.

Digital

printing process image

For Example:

Poster printing

design

Advertising printing design

Name

card / greeting card printing

Magazine

printing design

Packaging

printing design

Bag

printing design

Shirt

printing design

How to Design a Print Ready Business Card

Design in illustrator

Step 1:

Setting up your document

First step need to create

a new document in Illustrator. The business cards should be 88x55mm, but the

size may be can be vary across different print firms and enter the dimensions

to the width and height options and the bleed amount below. Cards being double sided

change the number of art boards option to 2. And then check your color mode is

set to CMYK.

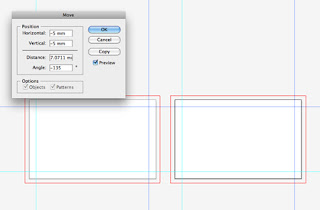

Step 2:

Drag out guides and

align them with the black outline of the cards (Press CMD+R to toggle rulers

on). Select the bottom horizontal guide and the two left vertical guides and

then hit enter to open the move window. Enter the 5mm in the horizontal and

vertical fields then click OK.

Step 3:

Select the

remaining guide and then open up the move window once again, for these times

enter -5mm in the fields. Now right click the document and select the lock

guides. These guides are in place to identify a 5mm safe margin around the edge

of the business card.

Step 4:

Use the line tool

to draw a short line with a 10% black stroke. Copy (CMD+C) and Paste in Front

(CMD+F), then rotate it by 90degrees. Drag a selection across both objects and

drag them into the Swatches palette. Delete the two original lines left on the art

board.

Step 5:

Draw a white rectangle

across the first card, covering the whole template within the red bleed line.

Copy and paste this rectangle, then fill the duplicate with the previously

created pattern swatch. As the swatch repeats it will create a seamless grid

pattern.

Step 6:

Paste the line work

character into the business card document and change the stroke colors to 100%

Cyan. Don’t forget to tweak the fill and stroke used to create the pupils of

the eyes.

Step 7:

Move the character

into place so it sits on the left side within the red bleed line. The

illustration may extend beyond the margin guides, but keep the head within the

black outline as this is the final card size once cropped.

Step 8:

Draw a cyan filled

rectangle on the right side of the card. Run the right edge all the way to the

bleed outline, and line the overall dimensions up with the background grid

pattern. Use the Type Tool to enter your name in an impactful font. Here I’m

using the fantastic League

Gothic in white to reverse out of the cyan rectangle.

Step 9:

Continue adding

textual elements to the design, but at a smaller type size and set in Cyan. I’m

using some general profile links, but you might want to add the usual contact

details often found on business cards.

Step 10:

Select all the

elements used in the front side of the card and drag them over to the rear

while holding the ALT key. Align everything up to the outer bleed line then

delete the character, the background grid and contact details.

Step 11:

Change the white

background rectangle to Cyan, and then create another grid swatch but this time

use 30% Cyan as the stroke color. Drag this swatch into the Swatches palette

and add it to a duplicate background rectangle.

Step 12:

Stretch the rectangle

behind your name to fill the full width of the card and change the fill color

to white. Drag out one extra guide to identify the centre of the card, and then

use this guide to align up the text centrally. Switch the text color over to

Cyan then change the wording to a welcoming message.

Step 13:

The design of the card

is pretty much complete. We have the subtle grid background providing a base to

the design, the hand-drawn character and the all important contact details. On

the rear the color scheme is reversed, and the centre rectangle continued to

house a nice, fun message.

Step 14:

Press CMD+A to select

all, then use the shortcut CMD+Shift+O to convert all fonts to outlines, this

will help prevent any font related problems with the printer. Go to File >

Save As and select Adobe PDF in the drop down menu. In the PDF options, select

the appropriate printer’s marks in the Marks and Bleeds section. Trim and

Registration marks are often the most important, with Color Bars and Page

Information sometimes being left to be added by the printers themselves.

Step 15:

Open up the final

print file in Adobe Acrobat to check over the design. The two art boards from

Adobe Illustrator have been used to generate two pages in the PDF document,

leaving just this one file to email over to your printer of choice.

Comparison

of analog silkscreen and digital printing.

Analog silkscreen

Analog silkscreen different because it relies on silk screen to take the design. And then the design is the incorporated into t-shirt printing using a layering technique.

Analog

Printing Features

-Colors are laid down one at a time

-Separate silk screens for each color used

-Maximum print size is 32-inches by 45-inches

-Separate silk screens for each color used

-Maximum print size is 32-inches by 45-inches

- Lower cost for high volume jobs.

- Lays down thick, rich colors on reverse backgrounds.

Advantages

of Analog Printing

- need time and skill for design registration.

- sample may be different than bulk

-Ink is mixed for each job and allows

custom color matching

-Analog inks are more opaque than digital

-Inks are more affordable

-Analog excels at printing reverse colors

-Analog inks are more opaque than digital

-Inks are more affordable

-Analog excels at printing reverse colors

-Half tones not easy

Digital printing

Digital printing rely on four-process system that CMYK (cyan, magenta, black, yellow). This basis of digit printing. The digital system take an art file and reproduce it directly by sending it to the press.

The

Features of Digital Printing

-Four-color processing system to

create designs: Cyan, Magenta, Yellow and Black

-Does not require screens or plates

-The maximum print size on digital jobs is 120 inches.

-Does not require screens or plates

-The maximum print size on digital jobs is 120 inches.

Advantages of Digital

Printing

-Prints all colors in a single pass and

makes the process more efficient

-Since the process is digital, there is a perfect registration between individual colors

-No bleeds or traps occur because digital printers use butt registration

-Capable of reproducing any type of graphic

-Since the process is digital, there is a perfect registration between individual colors

-No bleeds or traps occur because digital printers use butt registration

-Capable of reproducing any type of graphic

-Half-tones no problem.

-Reduces prep time for efficient project completion

-Reduces prep time for efficient project completion

.JPG)